Chưa phân loại

Learn about technology in sublimation heat transfer on T-shirts

- What is sublimation heat transfer printing?

Sublimation heat transfer printing is a printing technology that uses heat pressure during the t-shirt printing process to press ink onto paper. Then from the surface of the paper, the printed image is transferred to the fabric surface to form letters and images in accordance with the requirements of the customer. Thermal transfer printing uses a type of paper commonly known as thermal transfer paper or thermal paper. When sublimation heat transfer, the thermal transfer printing paper closes quite important in this stage, so you need to use high quality, good thermal paper to ensure the thermal transfer printing process in the best state.

Unlike screen printing or decal printing, after printing, it will leave a layer of paint or a layer of decal on the fabric. For this method, after printing, the ink penetrates directly into the fabric, smooth and sharp.

2. Principle of sublimation heat transfer printing

Stage 1: Printing text and images on thermal paper: at this stage, the person in charge of printing the shirt needs to program the print in general available from the computer. Then use the printer to print the image onto the paper surface.

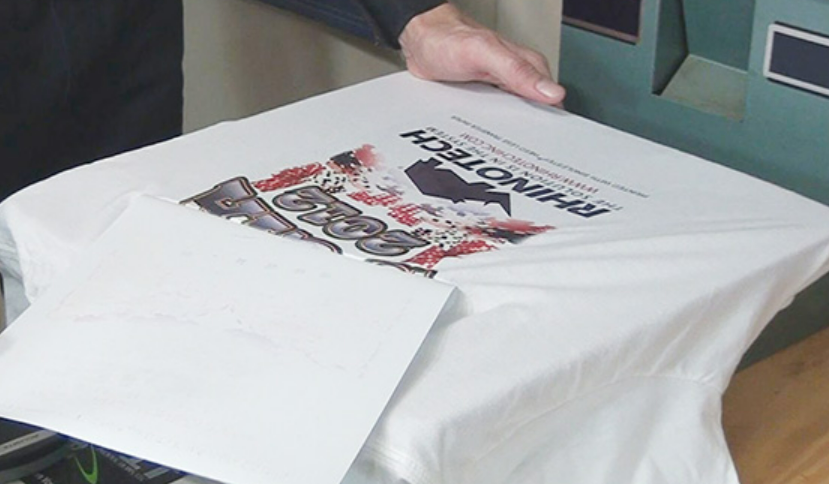

Step 2: Heat press from thermal paper to fabric surface: Place thermal paper on the surface of the fabric so that the print stays in the correct position to be printed. Usually, on the printing table, the frame rate and size are predefined. The second stage needs to use moderate heat. Not too hot nor too cold. Need to test before printing according to the process.

If when pressing heat from the printing paper to the surface of the fabric, the ink is still adhered. The staff will press again to ensure the absolute grip of the print.

About advantages:

Products are printed with high authenticity, high sharpness, and correct colors as required.

Prints are not limited to colors and images.

Has high adhesion, does not fade, does not crack the print. Customers can rest assured about the shelf life of the product.

About the downside:

Print materials when using this technology are limited. Usually, only promoting the best in terms of print sharpness, adhesion on materials with bright white surfaces such as white t-shirts, white porcelain cups, etc.

For printing on uniform fabrics, only fabrics with high PE content can be printed.

Prints may scratch on some materials that are prone to shrinkage.

Printers need to have skills and experience before being in charge of thermal transfer printing on products.

Cannot be edited if printed incorrectly.